Here the wires are in the mechanical room adjacent to the bilge compartment with the batteries.

From the mechanical room they pass thru a structural bulkhead and run under the

kitchen sink in the galley.

This shows the wiring under the galley sink and going thru the cabint behind the stove.

And finally they go thru another concrete and steal structural bulkhead into the engine room right at shelving where they connect to the controller and then to the motor.

But first, Carter will finish preparing the control board. Here the controller is mounted on an aluminum heat sink before all the control wiring is connected.

Here, Carter is making a termination on one of the welding cables. Each one is pressed on with a hammer and then soldered for a good connection.

And then a piece of shrink wrap to cover up the messy connections.

Before he can finish the motor Carter has to reroute the fuel line to the diesel engine because it was in the way of the chain.

Not a lot of extra room to move around the engine but it could be worse.

For a boat this is actually a pretty spacious engine room.

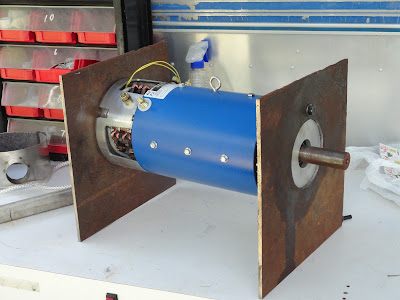

Close up of the motor with the wiring installed.

Here you can see the controller on the shelf with the electric motor on the left by the engine.

Just a few more details in the mechanical room and then we'll start her up!

Stay tuned.