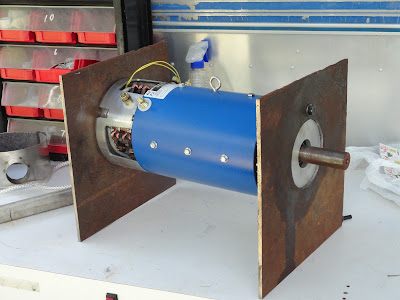

With an idea in mind he started out cutting two 1/4" metal plates for each end of the motor.

After shaping them to fit better he mounted two pieces of angle on each side.

Getting the mount lined up with the drive train was critical. There where a lot of weird angles with the hull of the boat sloping up and the drive line sloping down it was going to be tricky getting the shaft properly aligned.

He fastened a piece of aluminum to drive train sprocket to line up the support angle. This worked well.

Lugging the 100+ pound motor into the engine room was a chore.

But actually getting it mounted to steel supports in the engine room was a nightmare.

Blocking, shimming, drilling, bolting.

The chain lined up perfectly.

Dirty, sweaty, skinned knuckles, and sore back but success.

Now comes the hard part, wiring the darn thing up.

No comments:

Post a Comment